The team at Deakin University Institute for Frontier Materials (IFM) have created a revolutionary new process to extract silicon from used solar panels, which can then be reconfigured to create nano-silicon. With a market price of around $45,000 per kilogram, the nano material is highly sought after and holds huge potential for industrial use.

As much as 100,000 tonnes of solar panels will be available for recycling in Australia by 2035. With Victoria banning the panels from being sent to landfill and Queensland also considering a ban, better local recycling methods are needed. Solar panel recyclers currently reclaim only a small amount, approximately 17%, with many precious materials like silicon going unrecovered.

"Solar panel cells are fabricated using high-value silicon, but this material cannot be reused without purification as it becomes highly contaminated over the 25 to 30 years of the panel's life," said lead researcher, Dr Md Mokhlesur Rahman.

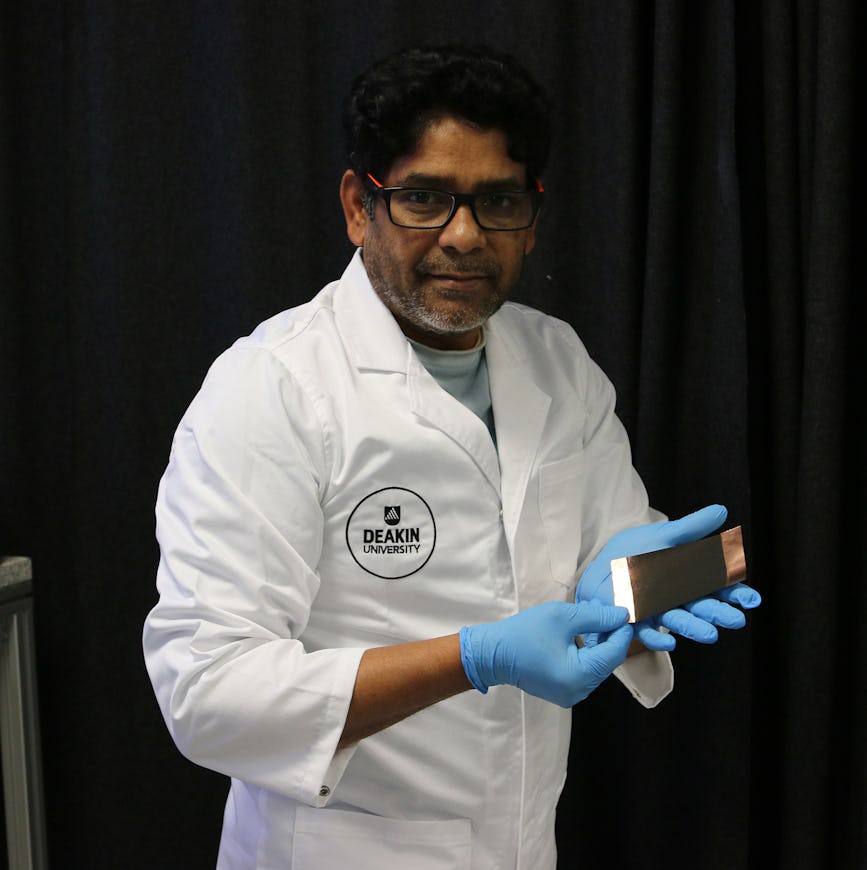

Lead researcher Dr Md Mokhlesur Rahman holding an anode made of nano silicon extracted from used solar panels (Image source Deakin University).

"We have developed a process that returns silicon collected from used cells to greater than 99 per cent purity within a day and without the need for dangerous chemicals. This thermal and chemical process is far greener, cheaper and more efficient than any other technique currently on the market.”

Once purified, the IFM team use a ball-milling process to reduce the silicon down to nanoscale and transform the material into a battery anode. This new anode has been shown to enhance performance by up to ten times for lithium-ion batteries, commonly used in electric cars and to store energy.

"We are using that nano-silicon to develop low-cost battery materials that will help deliver the higher performing, longer lasting, affordable battery technology critically needed to drive Australia's clean energy transition," said Dr Rahman.

The Deakin University team are working to upscale their research, design a large-scale commercial production line and find long-term industry support to catapult the Australian innovation into a global recycling industry worth millions.

“The work being conducted by Deakin University is an excellent example of recognising the value of recovered resources that would otherwise be discarded,” said Dr Nicole Garofano, Head of Circular Economy Development, Planet Ark.

“We often think that waste is low value. With this process, the IFM team have not only managed to recover a scarce resource, but they have converted it into a material with high economic value that can deliver better performance and reduce virgin material consumption. The project is a win-win for positive impacts,” she added.

It’s encouraging to see the benefits that can come from environmental policy, like banning solar panels from landfill, that help to motivate valuable innovation to reduce waste right here in Australia.

Planet Ark does not take responsibility for the accuracy of the original information and encourages readers to check the references before using this information for their own purposes.